Stainless steel square pipe is a hollow long strip of steel. Its cross-section is square, so people call it square pipe. The even shape provides steady strength in every direction. This makes it perfect for tasks that need reliable support all around. These pipes see broad use in building designs, factory setups, and home projects.

Stainless steel square tubing serves as a favored option for various building and assembly jobs. It offers solid strength and lasting durability. You can find it in frame structures, guardrails, furnishings, outer walls of buildings, car exhaust parts, food handling gear, and even boat fittings.

The advantages of stainless steel in square pipe shape include strong resistance to rust, high pulling strength, extended lifespan, pleasing looks, and simple upkeep. Stainless steel fights off rust well. It stands up to damage from many chemicals. This quality fits it for tough, harsh settings.

Stainless steel square pipe sizes use three key measures: outer dimension (OD), wall thickness, and length. The outer dimension means the width of the square side. Wall thickness sets the pipe’s toughness and weight-holding power. Length comes in usual or made-to-order sizes.

A big difference exists between nominal size and actual size. Nominal sizes act as basic labels, like 50x50mm. Actual sizes consider small production variations and may differ a bit. For instance, a 20mm x 20mm stainless square pipe with 1mm wall thickness often goes into making display stands.

Exact sizing matters greatly in building and making things. It ensures smooth joining with other parts. It also keeps the whole structure strong and safe.

Many global rules control stainless steel square pipe dimensions. The top ones people refer to include:

Allowed variation limits matter a lot. They set okay changes in size. This keeps products uniform. Both metric (millimeters) and imperial (inches) ways appear, based on local habits.

Wall thickness means the space between the inside and outside walls of the tube. It affects weight and sturdiness in a big way. Usual thicknesses go from thin ones, like 18 or 16 gauge, good for pretty or light-duty uses. Thicker ones, like 10 or 12 gauge, suit heavy loads.

People show wall thickness in millimeters or gauge numbers. Thin walls fit furniture or showy items. Thick walls work for carrying loads or high-pressure spots.

The usual outer dimensions for stainless square pipes go from 10mm x 10mm to 500mm x 500mm. You can sort them into:

A 100mm x 100mm pipe with 3mm wall thickness gives enough backing for a mid-size shelter.

Regular business lengths cover:

Standard lengths range from 1 meter to 12 meters. The 6-meter one (or about 20 feet) stands as the most popular. Yet, custom-cut lengths come easily on request. They match exact project needs.

Picking the right size relies on weight-holding ability, support demands, space limits, and fitting with other pieces.

For example, in bridge building, main support pipes need to be big. They also require thick walls to handle traffic weight. On the other hand, a 25mm x 25mm pipe suits tight spots like indoor furniture.

Style choices also shape size picks. Bigger sizes create a strong visual impact. Smaller ones bring clean, simple charm.

In harsh or sea settings, people choose thicker-walled pipes. They also pick better materials like SUS316L for stronger lasting power.

Choices always balance cost, weight, and rust fighting. Heavier walls guard better but raise material price and heft.

Close tolerances make sure pipes join perfectly in setups or builds. They avoid extra fixes. Bad control on tolerances can cause wrong alignments. It may also weaken how things work.

Makers follow tolerance rules like ±0.5mm on OD and ±10% on wall thickness. This keeps batches even.

Exact tools like calipers, micrometers, and laser scanners help in quality checks. Tight control on size differences and surface checks for each item ensure every pipe hits its targets.

Even wall thickness along the pipe’s full length matters. It keeps mechanical traits steady under pressure.

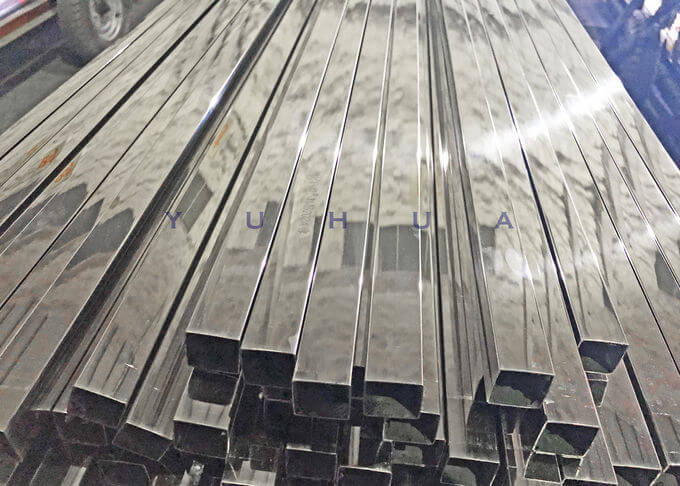

At YUHUA, we focus on providing top-quality stainless steel square pipes. We use modern making methods and strict quality checks. We hold ISO 9001 and Sedex certifications. We have 10 patents and rank as a national high-tech company.

With our factory setup and skilled engineering group, we give solid tech help and quick after-sales care to clients worldwide.

We produce stainless steel square pipes with outer dimensions from tiny ones like 10x10mm to bigger ones such as 200x200mm. Wall thickness choices go from light use (0.5 mm) to heavy tasks with over 5 mm thick.

Our 1.5-meter 20x20mm square tubes come from grade 304 stainless steel. This shows how we make special lengths for accurate setups.

Our custom options include exact cutting to any length the customer wants. We also supply special alloy types like SUS304L or SUS316L based on rust needs. Made-to-order cut lengths follow client details. This gives the best fit with little waste.

A: Nominal size refers to the general dimensions used for identification purposes. Actual size is the precise measurement including wall thickness. For example, a “50x50mm” pipe may have an actual outer dimension slightly different due to manufacturing tolerances.

A: Yes. Most suppliers, including YUHUA, offer cutting services. They let you set the exact length for your project.

A: Tolerances vary depending on the manufacturing standard used (e.g., ASTM A554). However, typical tolerances may be ±0.5mm for outer dimensions and ±10% for wall thickness unless otherwise specified by the client or standard.