Engineers in fields that require high accuracy often select stainless steel rectangular tubes. And this choice is far from random. These parts blend solid dependability with flexible design options. That makes them perfect for tasks needing both toughness and careful detailing.

Stainless steel rectangular pipe is a type of hollow long steel. People use it widely as a pipeline for moving fluids. Examples include oil, natural gas, water, gas, and steam. Besides carrying fluids, their design fits tight tolerances well. It also ensures steady fitting. The sharp, clean edges help with easy alignment and precise fitting. This is key in precision engineering.

Corrosion resistance is another big reason for their appeal. Stainless steel resists corrosion effectively. It stands up to damage from many chemicals. So, it works well in harsh settings. Even in chemical plants or ocean areas, these tubes keep their shape over time. Plus, the strong strength-to-weight balance cuts down on total system weight. Yet, it keeps structural firmness intact.

The rectangular form does more than look good. It boosts mechanical results a lot. Compared to round pipes, rectangular shapes spread loads more evenly. For that reason, they become the top pick for supporting frames, machine bases, and robot arms.

Flat sides on stainless steel rectangular tubes simplify welding and putting together. You can line them up easily. Then, you apply exact welds. This leads to smooth connections. All of that is crucial when you need strict tolerances. Also, their shape provides steady geometry. That supports better setup in automated setups. As a result, it lowers shaking and mistakes.

Stainless steel rectangular tubes are essential items in many sectors. Experts value them for lasting quality, flexibility, and attractive style.

Mechanical power is a key attraction. Stainless steel shows high hardness and great strength. Because of that, it handles wear well and resists pulling forces. So, it suits tough work conditions. When you need parts that endure high pressure, shaking, or ongoing stress—like in automation or aerospace—stainless steel rectangular tubing performs reliably.

They provide excellent size stability too. Even with heat or shaking, they hold their form and position. This reliability lets engineers skip extra fixes or adjustments. The material’s strong pulling strength allows it to hold and bear weight for a long period.

Upkeep is a further plus. These tubes work steadily for years with little care. That cuts downtime and total costs over time.

Corrosion resistance goes beyond stopping rust. It keeps precision intact. Stainless steel offers strong protection against corrosion and wear. That leads to a long working life. If a part breaks down from chemical contact or moisture, its exact sizes can change. Then, mechanical function weakens.

This matters a lot in areas like aerospace, pharmaceuticals, and cleanroom medical gear. There, dirt or breakdowns are not allowed. Stainless steel rectangular tubes endure breakdown from various harsh chemicals. These include acids, bases, and strong solutions. Thus, they ensure enduring strength and function.

The aerospace field needs materials that are light but very sturdy. Stainless steel rectangular tubes give just that mix. They often go into airframes, supports, and parts where cutting weight is as vital as lasting strength.

Hospitals and labs need materials that avoid rust or pollution. That makes stainless steel a clear winner. These tubes fit well for frames safe in cleanrooms, surgery tables, or lab stands. There, cleanliness and power meet.

Exact motion requires firm structure. Rectangular SS pipes form the core of robot setups. They resist bending under repeated movement loads. Their flat sides also make it simple to attach sensors and line up parts.

Today’s building designs mix beauty with purpose. Stainless steel has a shiny metal glow and pleasing look. It fits decoration and other areas. From handrails to key parts in tall buildings, stainless steel rectangular tubing gives a smooth finish. It also matches tough engineering rules.

Not every stainless steel is the same. Grades such as 304 provide basic protection from corrosion and solid power. For rougher spots—like near the sea or in chemical sites—316 might fit better. It has extra molybdenum. Different grades like 304 or 316 give levels of corrosion protection and power.

Finishes count too. Shiny polished surfaces work well for decorative uses. Brushed ones give an industrial feel with good resistance to wear.

Wall thickness affects both load handling and weight. Thicker walls mean more strength but added heaviness. You need to balance it for your use. Overdoing it raises cost and bulk. Underd oing it risks problems.

Ensure your chosen tube matches your tools. This is especially true for cutting or welding. Stainless steel surfaces are smooth and neat. They don’t pick up dust or grime easily. So, cleaning and upkeep are straightforward. Grades like 304 suit standard making methods well. Examples are TIG or MIG welding.

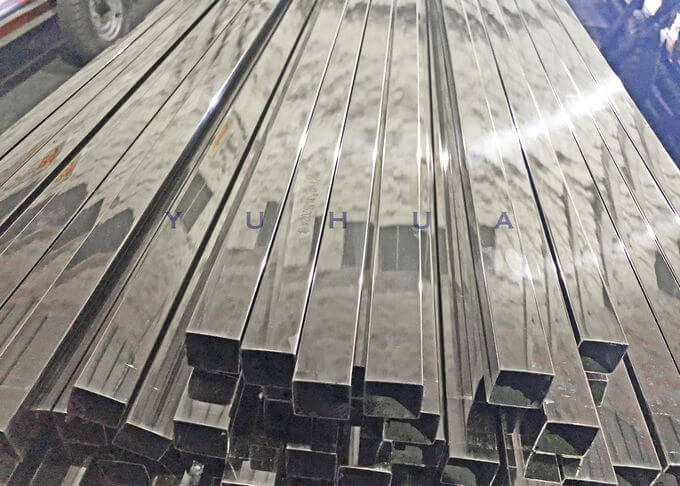

YUHUA started in 2009 in Nanhai District, Foshan City. It is one of China’s leading stainless steel companies. Our stainless steel rectangular pipes use top grades like 304 and 316L. This guarantees good results in uses from building to medical making.

We supply reliable stainless steel products. We also give strong technical help and solid after-sales support. Our items have even finishes, exact sizes, and steady quality. All of that is vital for precision engineering.

We are more than a basic supplier. We act as your engineering ally. Experts rely on our stainless steel rectangular pipe. We always meet global rules like ASTM A554. Products face tough quality checks to fit international standards.

From robotics to building design, our clients pick us. We provide what counts: exactness, power, dependability. And we offer quick delivery times too.

A: Rectangular pipes have longer sides compared to square ones, which allows better load distribution in certain structural applications.

A: Grade 316 is typically best due to its superior resistance to chlorides found in saltwater environments.

A: Absolutely! We specialize in custom fabrication tailored to your project’s requirements—just get in touch with our team.

A: Yes, our products meet ISO 9001 standards and comply with ASTM specifications like A554 for welded mechanical tubing.