304 stainless steel is a total crowd-pleaser. It’s got a sick mix of not rusting, being super tough and not costing an arm and a leg. 304 Stainless Steel Pipes are one of the most widely used stainless steel products, known for their excellent corrosion resistance, high strength and versatility. Jam-packed with chromium and nickel, it’s awesome for things like building stuff, food prep, car bits and chemical pipes.

It doesn’t react with stuff, so it’s perfect for squeaky-clean places like food and medical spots. It is suitable for the processing, storage and transportation of food. It’s easy-peasy to shape and welds like a dream. Plus, it stays solid in crazy hot or cold temps, making it a go-to for all sorts of gigs.

The best thing about killer 304 stainless steel tubing is how it laughs off rust and chemical gunk. Corrosion Resistance: Excellent resistance to rust, oxidation and most chemicals. That’s huge in wet or nasty spots. Chromium throws up a shield to stop rust and nickel keeps it chill.

Stainless steel has good corrosion resistance and is able to resist the erosion of many chemicals, making it suitable for various corrosive environments.

Strength is a major win. Top tubing’s got mad power and hardness but stays bendy for shaping. Stainless steel has high hardness and high strength, which makes it have good wear resistance and tensile resistance.

Welding is a piece of cake. You can stick pieces together without breaking the vibe, so custom stuff is no sweat. Easy to Weld and Fabricate: Ideal for custom designs and modifications.

A smooth surface ain’t just for show—it’s a must for keeping things clean, especially in food or medical gear. Polished or brushed finishes keep bacteria away by staying super sleek.

Perfect sizing means tubes slot right into bigger setups. Well-made tubing saves you from wasting stuff during setup and keeps things running like a charm.

To keep every batch legit, awesome 304 stainless steel tubing suppliers do hardcore checks every step.

It all starts with testing what the raw materials are made of. Only certified stuff that hits ASTM or similar rules gets the thumbs-up to keep quality dope.

While it’s being made, cool tools watch wall thickness, diameter, straightness and roundness right then and there. This catches screw-ups early so they can fix ‘em fast.

Non-conforming products are rejected or reprocessed before reaching final inspection—a key step in upholding product integrity.

Sticking to rules like ASTM A554 makes sure tubing is up to snuff on strength and size. ASTM A554 SUS304 stainless steel is a high-performance material renowned for its exceptional corrosion resistance, durability and aesthetic appeal.

Certifications like ISO keep a lookout on how stuff’s made, like green practices (ISO 14001) or quality control (ISO 9001).

You can trace every tube back to its batch with heat numbers or lot codes. This keeps everything straight-up across the supply chain.

Mill test certificates (MTCs) usually tag along with shipments, showing what’s in the metal and how strong it is.

YUHUA located in Muyuan Industrial Zone, Shishan Town, Nanhai District, Foshan City, is an established manufacturer specializing in stainless steel pipes including 304 grade tubing. As leading 304 stainless steel tubing suppliers in China’s industrial heartland, we offer a comprehensive range of products tailored for both domestic use and international export.

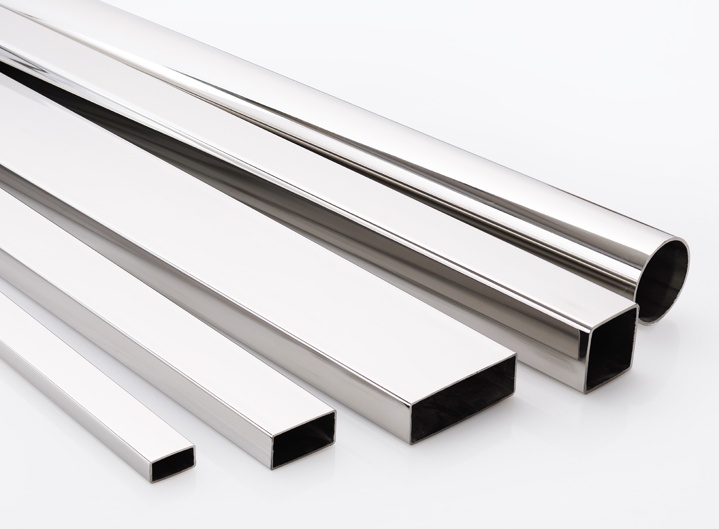

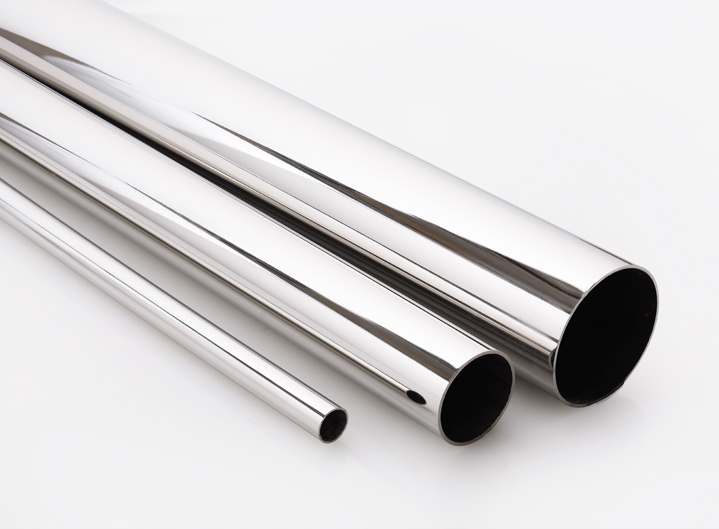

Our product line includes 304 Stainless Steel Pipe, available in round, square, rectangular shapes—each engineered with precision to meet diverse application needs.

We use wicked TIG welding tech and automated lines to nail sizing dead-on across our stuff. Our production strictly adheres to ASTM A554 specifications ensuring performance under demanding conditions.

Our spot’s got sweet testing gear like eddy current testers for weld checks and ultrasonic gadgets for wall thickness. Hydrostatic as pressure tests are also conducted upon request to validate pressure handling capabilities before dispatch.

Our tubes pop up in a ton of places:

-Construction: handrails, balustrades

-Food & Beverage: hygienic piping systems

-Automotive: exhaust components

-Furniture & Decoration: modern fixtures

-Industrial Equipment: fluid transport pipelines

Applications include architectural structures (handrails), decorative elements (furniture), food processing equipment, among others—making our products versatile solutions tailored to your specific requirements.

Ultrasonic waves hunt for sneaky flaws like voids or inclusions in the tube wall without wrecking it—making sure it’s solid before it ships.

Eddy current testing spots cracks or weird spots along welded seams by checking electrical conductivity changes—great for keeping welds tight during big runs. Eddy current testing for weld integrity

Salt spray tests act like tough conditions to see how tubing holds up. Samples might also get pitting tests with ferric chloride solutions per ASTM G48 standards—making sure they’re good for rough places like marine or chemical spots.

Solid packing keeps tubes safe on long hauls or rough rides. End caps block dirt and plastic sleeves stop scratches when stacking.

Wooden crates or metal frames beef up protection, especially for big overseas shipments via container routes.

For global folks needing stuff on time with no quality drama, packing’s as big a deal as making the tubes. Waterproof wrapping stops rust and barcode labels make customs checks quick, keeping international shipping smooth as butter.

Q: What certifications should I look for when choosing a 304 stainless steel tubing supplier?

A: Look for suppliers compliant with ASTM A554 standards along with ISO certifications like ISO 9001 (quality management) or ISO 14001 (environmental management). Mill Test Certificates should also be provided with each batch confirming composition analysis results.

Q: How does YUHUA ensure the dimensional accuracy of its stainless steel tubing?

A: We use automated forming lines combined with real-time monitoring tools during production stages along with post-production inspections using ultrasonic thickness gauges to guarantee precise dimensions on every tube we manufacture.

Q: Can I request custom sizes or finishes from a supplier like YUHUA?

A: You bet! We offer customization options including different lengths, diameters, wall thicknesses as well as surface finishes such as polished or brushed styles depending on your project requirements.