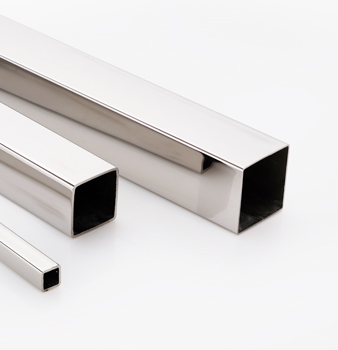

Different material types are often used to craft stainless steel Pipes.

304 Stainless Steel fights rust well and is very tough. It’s a handy pick for fields like construction, food processing, or car manufacturing. Its chromium and nickel levels make it great for practical or good-looking projects.

316L Stainless Steel stands up to chlorides and strong chemicals. It’s perfect for marine areas, drug manufacturing, or chemical plants. Its low carbon makes welding simple.

201 Stainless Steel is a wallet-friendly choice with decent rust protection. It’s good for less harsh settings, like decorative work, car parts, or building frames.

430 Stainless Steel resists rust in mild places. Its nice appearance suits architectural designs.

How much rust protection you need depends on the pipe’s setting. For example, 304 stainless steel handles rust and oxidation well. It works for indoor or outdoor jobs. On the other hand, 316L stainless steel is better for marine or highly corrosive spots. It deals with chlorides well.

For jobs needing strong pipes or load-bearing ability, grades like 304 or 316 stainless steel are great. They handle tough settings and provide solid strength. If you’re watching costs and needs are lower, 201 stainless steel is a smart pick.

The pipe’s purpose guides the material choice. For instance:

Construction: Tough grades like 304 or 316L are common.

Decorative Projects: Grades like 201 or 430 look attractive.

Food Processing: 304 stainless steel keeps things clean and safe.

YUHUA offers quality stainless steel Pipes. They suit many needs with products made from top materials, like ASTM A554 SUS304 stainless steel. This grade fights rust well and is easy to care for, ideal for building designs or factory equipment.

Our skilled team helps customers choose pipes that match their needs. They ensure pipes hold up in marine settings or look great in decorative work. Visit our website to check out our products!

A smooth surface on steel Pipes boosts both looks and function. Polished finishes make pipes look better and stay cleaner, which matters for food processing equipment.

Brushed finishes give a stylish, modern look for building designs. Matte finishes cut down glare when needed. Different finishes also help stop rust by reducing spots where dirt can stick.

At YUHUA, we understand tolerance is key in manufacturing. It keeps pipe sizes steady during production. Precise tolerances ensure pipes stay strong and fit easily during setup. Our products, made with careful engineering and meeting ASTM standards, offer reliable quality.

Picking the right material grade means knowing your project’s specific needs. Think about surface quality and precision. With YUHUA’s experience and wide product range, you can choose a pipe that works well and lasts long.

In construction, the material grade for steel Pipes depends on three factors:

Strength

Rust protection

Toughness

For instance, 304 stainless steel is widely used. It offers great rust resistance and strength.

This material is common in frameworks, handrails, and scaffolding. It holds up well in different weather conditions. As a result, it fits both indoor and outdoor projects.

For jobs in marine or chloride-heavy areas, 316L stainless steel is better. It resists pitting and crevice corrosion, perfect for coastal spots or chemical exposure. Its low carbon makes welding easier and avoids issues during the process.

201 stainless steel is a cheaper option for construction. It’s less rust-resistant than 304 or 316L but works in mild conditions. It’s often used for decorative features like railings or dividers.

YUHUA provides quality stainless steel Pipes for construction. Our products, made from materials like ASTM A554 SUS304 steel, blend strength and good looks. Check our collection here!

In industries with harsh conditions, like high pressure or chemical exposure, 316 stainless steel is a top choice. It handles acids and alkalis well, making it great for chemical plants, drug production, or marine engineering.

304 stainless steel is popular in industrial settings. Its rust resistance and strength make it ideal for food processing plants, car exhaust systems, or machine parts.

For projects with tight budgets or less demanding settings, 201 stainless steel is dependable. It’s used in equipment needing moderate rust protection and is cost-effective for big projects.

At YUHUA, we get industrial needs. Our steel Pipes are built to meet high quality and reliability standards. Whether for chemical transport or machinery, our team helps you pick the best material grade.

Q: Why is 304 stainless steel a good pick?

A: 304 stainless steel fights rust well and is very tough. Its flexibility fits construction, food production, and more.

Q: Why use 316L stainless steel in marine areas?

A: 316L stainless steel handles chlorides and harsh chemicals well. Its low carbon improves welding, making it ideal for marine or chemical settings.

Q: How does YUHUA keep products high-quality?

A: YUHUA uses strict quality checks during production. We meet global standards like ASTM A554 to ensure strength and performance.

Curious about YUHUA’s products? Visit our website for a full look at our stainless steel Pipes, made for various uses.

By understanding how different material grades work for specific tasks, you can pick stainless steel Pipes with confidence.