Square pipe manufacturers handle the task of turning basic metals into empty, square-form tubes. These tubes fit many practical and visual needs. The making process usually starts by picking suitable raw items. Such items include carbon steel, stainless steel, aluminum, or galvanized steel.

They apply methods like welding, extrusion, and cold forming to form metal into square tubes. For welding, high-frequency electric resistance welding (ERW) often joins the edges of bent steel strips. This creates smooth square forms. Extrusion works better for non-ferrous metals, such as aluminum.

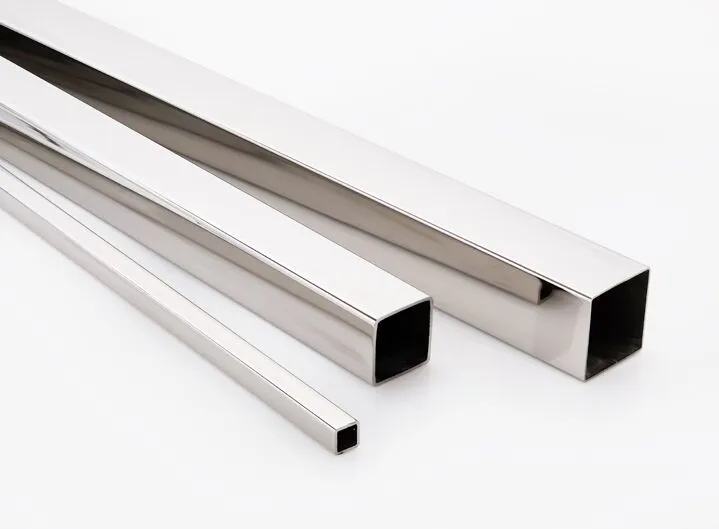

Once the main shape forms, rollers press and mold the round tube into its square profile. Cooling comes next to steady the material. The last steps involve slicing the tubes to size, smoothing edges, and adding surface treatments like polishing or galvanizing.

Quality checks happen throughout to maintain reliability and toughness. This covers eddy current testing for weld strength, hydrostatic pressure tests, and careful size measurements.

Square pipes gain popularity in fields that need both power and visual charm. They appear often in building work, furniture creation, and vehicle production. Their empty design and even cross-section offer firmness in weight-support tasks. At the same time, they keep the overall mass light.

Square pipes ensure top safety in numerous fields. These range from building and upkeep to vehicle building. They provide flexibility, power, and style. In structures, they act as key supports for frames and supports. In furniture, they form trim legs and base frames. This stems from their fresh style and firmness. In vehicle uses, square pipes often build chassis bases and safety cages.

People also use them in barrier setups, grip rails, storage units, sign stands, and even creative displays. The tube delivers steady results and versatility. Thus, it remains a vital item in industry and more.

Yes, they can. A main service from square pipe manufacturers is tailoring. They adjust sizes, wall depth, and material types to match client details. This adaptability fits various weight loads, style looks, and weather settings.

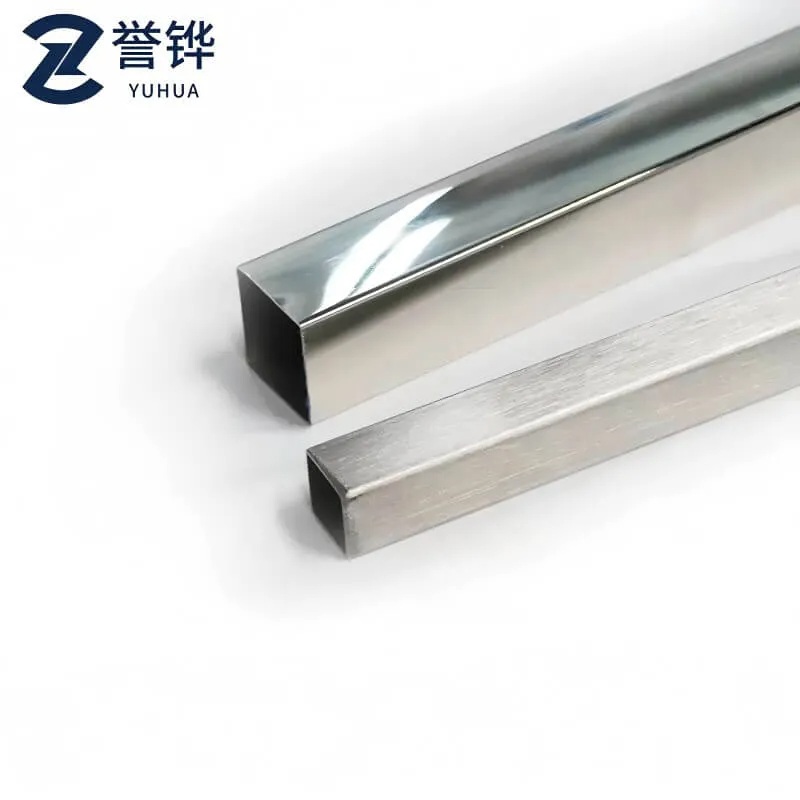

Buyers can pick special surface options like brushed, polished, or annealed. Custom options such as polished or brushed surfaces work well for display purposes. Unique orders for grooved pipes or tubes with special edge curves can fit, based on the maker’s skills.

Many makers also give extra services. These include hole drilling, laser slicing, or angling ends for exact fitting needs.

To guarantee quality and fit across fields and areas, pipes usually follow ASTM, DIN, or ISO rules by location. For instance, ASTM A500 covers cold-formed welded carbon steel structural tubing in round, square, and rectangular forms. ASTM A554 handles welded stainless steel mechanical tubing for display and structural roles.

These rules assure fit, safety, and results across fields. Plus, makers might supply papers like ISO 9001 or Sedex. These show they meet quality system rules.

Stainless steel ranks as one of the top picked materials for square pipe making. It fights rust well. This suits it for open-air and damp spots. So, it works for design elements like grip rails or barriers. It also fits sea and chemical settings.

It gives a neat appearance that matches both work and display uses. Be it a shiny 304 square tube for fresh furniture or a tough 316L tube in chemical plants, stainless steel covers both practical and style demands.

Stainless steel’s build strength lets it handle big strain and wild temperatures without losing form firmness.

When picking a square pipe manufacturer, think about key points:

Also, see if the maker gives quality proof files. Examples include mill test certificates and rule-following like ASTM A500 or A554.

Yes. Most makers provide samples to check quality before full runs. Samples let you test wall depth, surface treatment, straight form, weld firmness, and match with other parts. This happens before a big buy.

This step matters a lot for tasks where looks or exact fits count. Think custom furniture or design railings.

At YUHUA, we focus on making top-notch stainless steel square pipes. We shape them to fit varied task needs. YUHUA started in 2009 in Nanhai District, Foshan City. It stands as one of China’s leading stainless steel firms. Our range covers grades like 304, 316L, 201, 410s/430. Each brings perks in lasting power and looks.

Our setup, quality, output, and growth match world levels. From rust-proof building tubes to trim display items for fresh spaces, our stainless steel square pipes aim to work well.

We supply many sizes. This includes the favored 1.5 Meter 20x20mm 304 Stainless Steel Square Tube with annealed surface finish for better shine.

We run our own factory and have a trained engineer group. This lets us create tailored items for buyers. Be it close size limits or special treatments like mirror-polished tubing, we provide quick and sure delivery.

We hold ISO 9001 certification to support our precision making and strict quality checks. That is why firms worldwide rely on YUHUA for stainless steel tubing needs.

A: Square pipes have equal width on all sides while rectangular pipes have one side longer than the other; both serve structural purposes but are chosen based on design requirements.

A: Yes, most manufacturers offer custom cutting services so that pipes arrive ready for installation without further modification.

A: Absolutely—stainless steel resists rust and corrosion, making it an excellent choice for outdoor structures like railings or frames exposed to weather elements.