Stainless steel tubes see broad use in building, furniture making, factory gear, and building ornamentation. Many people picking stainless steel tubing pay close attention to material type, outer layer, or wall depth. Yet, tube shape—round, square, or rectangular—plays an equal role in how well it works, its look, and value for money.

Each tube shape handles weight in its own way. It reacts differently when being shaped. And it gives a unique style in the final setup. Picking the incorrect shape can cause extra material loss. It might cut down on building strength. Or it could raise making costs. Knowing how round, square, and rectangular stainless steel tubes differ in function helps designers, builders, and purchasers make better choices based on the task at hand.

On a simple level, the main difference comes from the cross-section form. Still, this form has a direct effect on how strength spreads out. It also impacts how it behaves during making. And it influences how it performs in use.

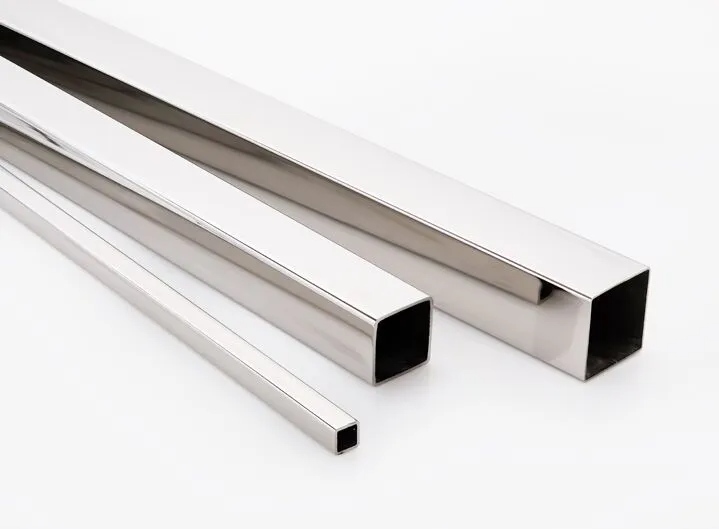

Round stainless steel tubes have a round cross-section without any edges. Square tubes come with four matching sides and sharp corners. Rectangular tubes, on the other hand, have sides of different lengths. This creates one longer side and one shorter one.

Round tubes spread stress out evenly across the full circle. This makes them great for tasks with inside pressure or twisting forces. Square and rectangular tubes place material away from the middle. As a result, they hold up better against bending. They also stay stiffer. This proves useful in frames and building roles.

These variations mean no one tube shape fits every situation. Each one suits certain weight types and setup needs.

Round stainless steel tubes rank among the most popular forms. They offer good mechanical value and all-around use.

The round form lets stress move smoothly around the tube. For that reason, they suit tasks with pressure, shaking, or turning forces well. That explains their common role in pipelines, machine setups, and handrail builds.

Round tubes also bring ease in shaping. They bend, curve, and shine up more simply than those with angles. Joining them by welding goes smoothly too. There are no edges needing extra care.

Typical applications include:

Round tubes shine when a sleek look, even strength, and simple making are top concerns.

Square stainless steel tubes mix strength with good looks. Their even sides and sharp corners ensure solid lining up. They also offer strong contact areas. That’s why they appear often in frames and piece-together builds.

Square tubes stand up to bending better than round ones in direct paths. Plus, their flat sides link easily to parts like sheets, boards, or holders.

Visually, square tubes give a fresh, shaped style. It suits furniture, building details, and metal decor nicely.

Square tubes provide:

For these reasons, people often select them for furniture bases, shelf units, barriers, and frame structures. Both toughness and style count there.

Rectangular stainless steel tubes resemble square ones. But they focus on tasks needing power in one main way.

Stretching material along one side boosts bending hold in that line. At the same time, it keeps weight low. So, they fit beams, props, and frames with clear weight routes.

Rectangular tubes save space too. Their narrow form slips into close building or machine spots. Square or round ones might not work there.

Rectangular tubes are commonly used for:

They work best when builders want power without added size.

| Feature | Round Tube | Square Tube | Rectangular Tube |

| Load Distribution | Uniform | Balanced | Directional |

| Bending Resistance | Medium | High | Very high (one axis) |

| Torsional Strength | Excellent | Moderate | Moderate |

| Fabrication Ease | Easy | Easy | Moderate |

| Visual Style | Smooth and classic | Modern and geometric | Industrial and functional |

| Common Uses | Pipelines, handrails | Furniture, frames | Structural supports |

This comparison makes it clear. Pick the shape based on what the task requires. Not just on what you like.

To pick the right stainless steel tube shape, think about:

No single shape works best for every task. The top pick is the one that meets the needed function. It should do so at the least expense and with the most gain for your exact situation.

At YUHUA, we focus on making stainless steel tubes. They handle the everyday needs of building, furniture, decor, and factory work. We create round, square, and rectangular stainless steel tubes. They come in many sizes, wall depths, and outer layers. This supports various setup and building demands.

Our making process stresses steadiness, accuracy, and adaptability. Customers can get tubes for frame builds, building parts, or decor uses. Our items are built for steady work and neat looks.

We use several stainless steel types. We also provide tailor-made choices to fit set rules, measures, and task needs. Drawing on our making know-how and tight quality checks, we guide customers to the best tube shape. This ensures lasting toughness and worth over time.

A: Strength depends on how the tube is loaded. Round tubes are strongest under internal pressure and torsion. Meanwhile, square and rectangular tubes offer better resistance to bending in structural applications.

A: Square and rectangular tubes are generally preferred for furniture. Their flat surfaces make assembly easier. They also provide a clean, modern appearance.

A: Choose round tubes for pressure-based or curved applications. Go with rectangular tubes when strength is required in one primary direction. Examples include beams or supports.