304 stainless steel is a well-known mix of chromium and nickel. It fights off rust and heat well. It keeps its strength in cold weather. This makes it great for lots of jobs, especially where toughness and cleanliness are needed. It deals with acids and alkalis in the air nicely. In busy factory areas, cleaning it often stops rust from forming.

It bends and joins easily. Lots of chromium and nickel make it strong against rust, wear and tough places.

304 stainless steel pipes are really popular. They hold up against rust, are sturdy and work for many tasks. These traits make them perfect for things like making food, working with chemicals, building houses and making cars.

It’s simple to shape and weld. Some 304 stainless steel is safe for food use. This lets it work in machines that make food.

At YUHUA, we focus on giving you great 304 stainless steel pipes. They follow rules like ASTM, AISI and EN. You can get them in different sizes, shapes and finishes. We use new ways to make them. Careful checks make sure every piece works well.

Pipes and tubes aren’t the same in how they’re sized or used. Pipes carry liquids or gases. They’re measured by their inside width. Tubes are for building things or making them look nice. They’re measured by their outside width.

Pipes are best when moving lots of liquid or gas is important. Think of water systems or chemical plants. Tubes are better when you need exact sizes or a good look.

At YUHUA, seamless pipes go through careful steps. We start by checking raw materials. Then, we do cold drawing. After that, we use heat treatments like annealing. Finishes like polishing or brushing make them precise and strong.

Pipes use NPS rules, which show a rough inside width. For example, a “1-inch” pipe isn’t exactly 1 inch inside or out. Tubes are measured by their exact outside width.

Tubes have set wall thicknesses, measured in gauge or millimeters. This changes how strong they are. Pipes use “schedule” numbers, like Schedule 40 or 80, to show wall thickness.

Exact sizes are key for building projects. Tubes have closer size limits, so they’re great for things like house frames or furniture. Pipes care more about holding lots of liquid than being super precise.

These pipes work well in building, food making and chemical work. They don’t rust easily, so they’re great for moving water or chemicals.

In building, they’re used for handrails, frames and scaffolding. They’re strong but not too heavy, so they hold up structures without adding extra weight.

Tubes have tighter size limits. This makes them perfect for medical tools or control panels where being exact is a must.

In air systems or power plants, moving heat matters more than liquid amount. Tubes do better because their walls are even.

Pipes often have plain, matte finishes for factory use. Tubes usually have polished or brushed surfaces to look nice.

Tubes come in polished, brushed or matte finishes for decoration.

It’s not always easy. Tubes often have cleaner edges because they’re made more precisely. Pipes might look chunkier, with thicker walls for handling pressure.

We start with good-quality materials. We check their chemical makeup to follow rules like ASTM A554.

Cold drawing makes sizes more exact. Heat treatments, like annealing, make the material bendy while staying strong.

Our seamless pipes last a long time. They have an even grain structure. We get this with advanced cold-working and careful heat treatments.

Tubes have stricter size limits than pipes. For example:

-Tube outside width limit: ±0.005 inch

-Pipe NPS limit: ±10% on wall thickness, based on schedule

This changes how well they fit when you install them.

Usually, no—if both are made from 304 stainless steel. But tubes might be a bit stronger. This comes from hardening during cold drawing.

Pipes are usually cheaper for moving lots of liquid or gas. They don’t need super precise work. Tubes cost more because of tighter size limits but look better.

Pick pipes for moving liquids under pressure. Choose tubes for building or looks. Think about the place they’ll be used. Stainless steel fights rust well in rough spots.

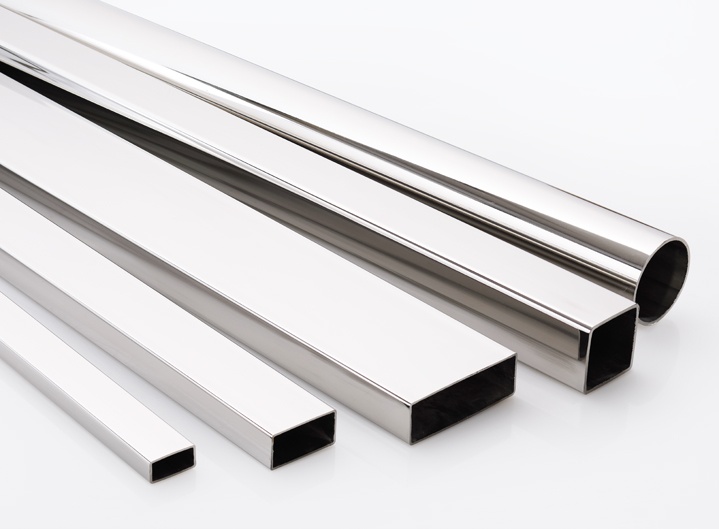

Yes, we make custom lengths, widths and finishes (polished, matte or brushed). Shapes can be round, square or rectangular. Everything is made to fit your needs. Contact us at Foshan Nanhai Yuhua Hardware Products Co., Ltd., in Muyuan Industrial Zone, Foshan City.

Q: Can 304 stainless steel seamless pipes be used outside?

Yes, they resist rust well, so they’re great for tough outdoor spots.

Q: Are your products certified?

Yes, they follow ASTM A554 and other world standards for trustworthiness.

Q: Do you make both welded and seamless options?

Yes, we make welded tubes under ASTM A554 and seamless pipes with new methods. This keeps them strong for all kinds of uses.