Picking the proper stainless steel tube goes beyond just cost or stock. The choice of material greatly impacts how well it works, how long it lasts, upkeep expenses, and overall safety in the long run. Among various choices, weighing 410 stainless steel vs 316 stainless steel stands out as a key and frequent choice for tube uses. Each type brings unique benefits based on the surroundings, physical needs, and what the project expects over time.

This piece breaks down the real-world contrasts between 410 and 316 stainless steel tubes. It explains where each one shines brightest. Plus, it guides engineers, purchasers, and project leads to smart choices.

Grasping the basic makeup of these two types marks the initial move toward smart material picking.

410 stainless steel is a martensitic type with more carbon and fair chromium amounts. This mix lends it solid physical traits, decent resistance to wear, and the option for heat treatment to boost hardness. Since it has minimal or no nickel, 410 stainless steel tends to cost less than austenitic types.

For tube and pipe uses, folks often pick 410 stainless steel when toughness and handling physical strain top the list over top-notch rust protection. It holds up nicely in dry spots or those with slight corrosion. You see it a lot in factory equipment, support pipes, and parts facing okay heat levels.

316 stainless steel falls into the austenitic group. It has greater nickel and molybdenum levels. That molybdenum boost greatly enhances defense against pitting and gap corrosion, particularly where chlorides abound.

Thanks to this blend, 316 stainless steel tubes thrive in sea settings, chemical work, drug making, and food handling. They stay non-magnetic when annealed. Also, they keep great toughness over a broad heat range.

The strength of a material and how it acts under pressure matter a lot in choosing tubes. This holds especially true for factory and building setups.

410 stainless steel gives better hardness and stronger wear defense than 316. So, it fits well for jobs with rubbing, shaking, or ongoing physical pressure. Yet, its lesser flexibility makes it less tolerant during big bends or twists.

By contrast, 316 stainless steel delivers top flexibility and sturdiness. It works steadily in high-pressure setups and places with heat growth, shaking, or steady strain. Though not as hard as 410, its steady physical balance leads to a longer lifespan in tough spots.

The gaps between 410 stainless steel vs 316 stainless steel show up more plainly in a head-to-head look.

| Property | 410 Stainless Steel | 316 Stainless Steel |

| Stainless steel family | Martensitic | Austenitic |

| Corrosion resistance | Moderate | Excellent |

| Strength and hardness | High | Moderate |

| Weldability | Requires control | Very good |

| Heat resistance | Moderate | High |

| Magnetic behavior | Magnetic | Non-magnetic |

| Typical cost | Lower | Higher |

| Best-use environments | Low to moderate corrosion | High corrosion, marine, chemical |

This side-by-side view shows why neither type wins every time. Rather, the right fit hinges on the work setting and what you value most in performance.

Past the makeup and toughness, how you shape the material often tips the scale between 410 or 316.

You can machine 410 stainless steel with ease. It takes heat treatment well. But welding needs close watch to dodge cracks from its extra carbon. For key joins, warming it first and treating it after often helps.

316 stainless steel welds and shapes more simply, above all in tricky pipe networks. Its low-carbon forms cut down even more on carbide buildup risks. This makes it great for jobs needing lots of welding.

The starting price of the material is just one piece. Over time, how it holds up and what it takes to keep it going often matter more than early savings.

410 stainless steel tubes usually come at a cheaper upfront price. They do fine in managed settings. Where rust risks stay low, this type gives strong value through the years.

316 stainless steel tubes cost more at first. However, they cut way down on breakdowns from rust. In harsh spots, their longer run and less upkeep needs make the extra spend worthwhile.

Once you get the tech contrasts, choosing a solid maker partner matters just as much.

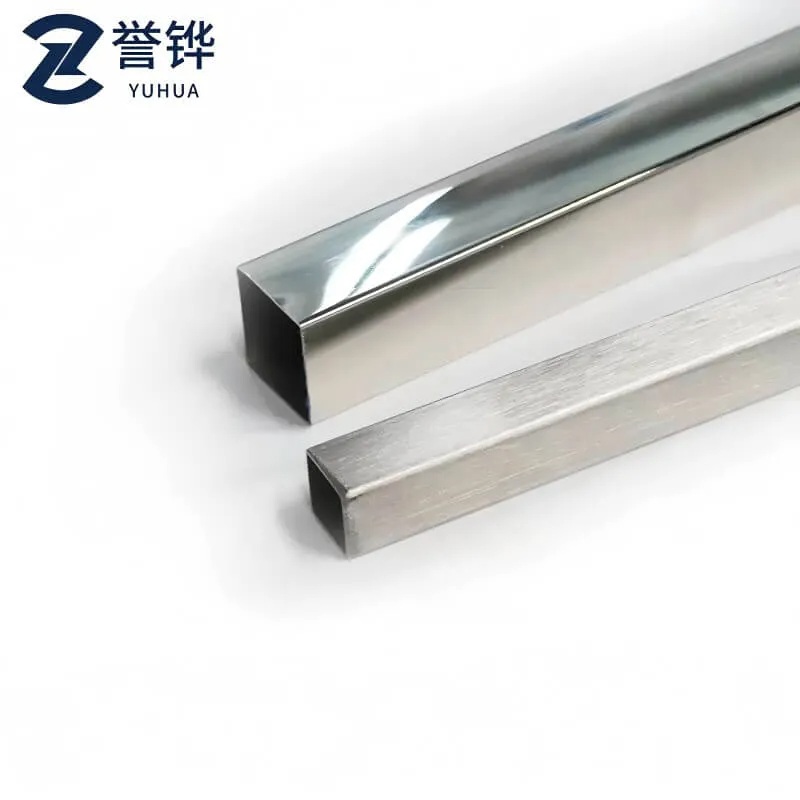

YUHUA has focused on making stainless steel tubes for years. We cover many types, including 410 and 316 stainless steel. Our aim is steady quality, exact sizes, and reliable work in factory, building, and support uses.

We build our 410 stainless steel tubes for strong toughness, fair wear defense, and even performance where rust stays limited. We handle heat steps and making closely to guarantee matching physical traits. So, these tubes suit machine frames, hold-up structures, and everyday factory tasks.

On the flip side, our 316 stainless steel tubes target tough conditions. We make them with tight checks on makeup and surface state. This ensures top defense against salts, chemicals, and dampness. You find them often in sea setups, chemical lines, and clean-sensitive spots.

YUHUA gets that varied jobs need varied fixes. That’s why we offer tweaks in tube size, wall depth, finish type, and length. We match material picks to actual work conditions. In turn, this helps buyers hit both solid reliability and smart spending.

Picking between 410 stainless steel vs 316 stainless steel ought to begin with the spot where the tube will work. If toughness and low price lead in a mild-rust area, 410 often makes sense. Where dampness, chemicals, or salt can’t be dodged, 316 offers a safer, tougher fix.

YUHUA teams up tight with buyers to check these points. We suggest the best material for their exact needs. Our aim goes beyond just providing tubes. We back wiser picks that cut dangers and boost results over time.

A: The key gap sits in rust defense and makeup. 316 stainless steel has nickel and molybdenum. These give it better rust resistance. Meanwhile, 410 stainless steel brings higher hardness and toughness but just fair rust defense.

A: Yes, 410 stainless steel tubes work outdoors in spots with low dampness and few harsh elements. For shore or chemical areas, 316 stainless steel fits better.

A: In jobs facing dampness, chemicals, or salt, 316 stainless steel usually gives stronger value long-term. That’s from less upkeep and more years of use. In mild-rust areas, 410 stainless steel can prove more budget-friendly.