Buttweld fittings are key parts in stainless steel (SS) tube welding, which join pipes and ensure a smooth flow of materials. These fittings get welded at the pipe ends, which forms a solid system and boosts the strength of piping networks. They’re durable, sturdy and handle high-pressure settings well.

Buttweld fittings are liked for SS tube welding because of their good physical traits and solid corrosion resistance. Stainless steel types like 304 and 316L are used in these fittings. They fight off rust, oxidation and harsh chemicals. 304 stainless steel is a common chromium-nickel kind. It’s good against corrosion and heat. So, buttweld fittings are great for tough jobs like chemical plants, food making and ocean settings.

Buttweld fittings make tubes last longer by getting rid of weak spots in piping. Welded joints form one piece with the pipe. This lowers leaks and stops problems in high pressure or heat changes. Stainless steel is hard and tough,which holds up against wear and pulling forces. Plus, the smooth inside of buttweld fittings lowers turbulence. It keeps the flow steady.

Welding buttweld fittings makes tough joints. These hold up under high pressure without trouble, which gives leak-proof joints needed for moving liquids or gases safely. Our products, like 304 stainless steel pipes, follow ASTM rules. They’re reliable in all kinds of conditions.

Buttweld fittings make a smooth switch between tubes. Their even shape avoids bumps or gaps. This lowers friction. It stops stuff from building up in pipes. This is really needed in places like food making and drug production where cleanliness is a big deal.

Stainless steel buttweld fittings are tough. They need less fixing over time. They resist corrosion, so they last in rough settings. Stainless steel stuff lasts a long time. It fights corrosion and wear well. You don’t need to replace or fix them often.

Buttweld fittings fit just right. They lower waste during setup compared to threaded or socket welds. This saves cash while keeping things strong.

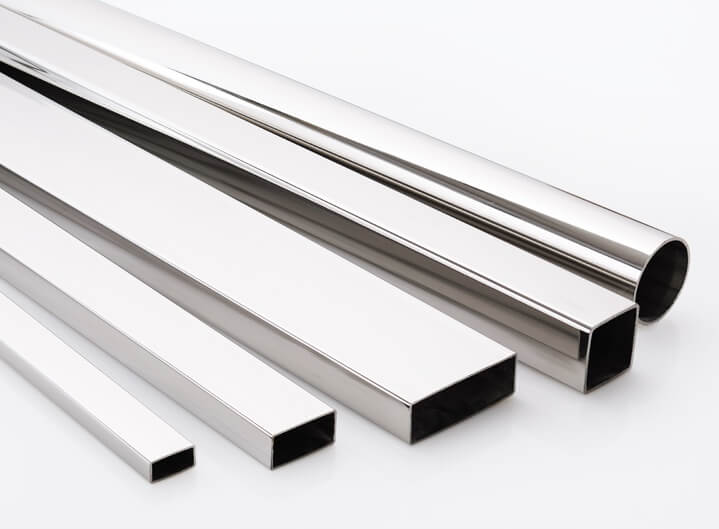

Buttweld fittings look clean and neat. They help with style and stability. Their shiny finishes are good for visible setups in building projects or fancy piping. Stainless steel’s bright shine adds beauty to its practical uses.

Buttweld fittings are often used in industrial piping where smooth joints are needed for good performance. They move fluids like water, oil, gas, steam and chemicals under different pressures.

In food and beverage, cleanliness is everything. Stainless steel buttweld fittings, made from types like 304L or 316L, meet hygiene rules. They resist corrosion from acidic or alkaline stuff in food production.

Chemical plants use stainless steel buttweld fittings because they resist acids or chlorides. 316L stainless steel round pipes handle chlorides, acids and alkaline solutions better. Drug production needs well-made parts. These keep products pure and handle tough cleaning steps.

At YUHUA, we’re proud to offer high-quality stainless steel pipes and tubes for all kinds of industrial needs. Our big range includes 410 stainless steel pipes and square tubes, well-made to meet global standards.

At YUHUA, we’ve got a big range of stainless steel products for SS tube welding. Our catalog has 410 Stainless Steel Pipe, 304 Stainless Steel Pipe, Stainless Steel Round Pipe, Stainless Steel Rectangular Pipe, Stainless Steel Square Pipe and 201 Stainless Steel Pipe. These work for all sorts of industrial and business uses while keeping top quality and performance.

Our 304 stainless steel pipes are super flexible. They’re good against corrosion and tough. 304 stainless steel is a widely used chromium-nickel type. It fights corrosion and heat well. Our 316L stainless steel round pipes are awesome for harsh settings. They resist chlorides and tough chemicals better. We also have 201 stainless steel pipes as a cheaper option for projects needing strength and okay corrosion resistance.

We stay ahead by coming up with new solutions for SS tube welding. We use top-notch TIG welding tech and strict quality checks. This makes our products dependable. All our stuff meets global standards like ASTM, AISI and EN. They’re good for industries from building to drugs.

YUHUA’s quality focus isn’t just about making things. We give full material tracking, mill test certificates and pressure testing if you ask. This shows we care about giving reliable products that fit what clients need.

YUHUA’s high-tech manufacturing really helps buttweld fittings in SS tube welding. Our fittings are well-made for smooth pipe links. They lower weak spots in piping. Welded joints form one piece with the pipe. This cuts leak risks. It stops issues in high pressure or heat changes.

Our buttweld fittings have smooth insides. These help flow by lowering turbulence and stopping buildup. This is key in places like food making and drug production where hygiene is critical. The good weldability of stuff like 304L and 316L stainless steel makes tough joints. These hold up in extreme conditions without failing.

By mixing new methods with high-quality materials, we make buttweld fittings that beat industry standards. Our skills let us offer solutions for tricky uses while keeping costs low.

Q: Why do people like buttweld fittings over other pipe joints?

A: Buttweld fittings are liked because they make smooth joints. These help strength and lower leaks. Their smooth insides improve flow, great for moving liquids or gases under high pressure.

Q: What materials are usually used for buttweld fittings?

A: Typical materials are stainless steel types like 304L and 316L. They’re good against corrosion and have solid traits. 316L stainless steel round pipes fight chlorides, acids and alkaline solutions better.

Q: How do buttweld fittings save money over time?

A: Stainless steel buttweld fittings are tough and lower upkeep costs. Their corrosion resistance means they last long even in rough settings.

Q: Do YUHUA’s buttweld fittings meet global standards?

A: Yup, all our products follow standards like ASTM A554 and AISI certifications. They’re dependable in all kinds of conditions.

Q: Can I change the size of buttweld fittings from YUHUA?

A: For sure! We offer custom sizes for outer diameter (OD), wall thickness and length to fit your project.