Stainless steel 304 square pipe serves as a popular structural and decorative element. People value it for its toughness, ability to resist rust, and pleasing look. 304 stainless steel pipes rank among the most common stainless steel items. They stand out due to their strong resistance to corrosion, solid strength, and flexibility. The high levels of chromium and nickel in it give grade 304 better protection against rust, rusting, and damage from the surroundings.

304 stainless steel square tubing shows great resistance to corrosion and high pulling strength. It works well in indoor settings and outside areas alike. This quality suits it for many fields, from handling food to building projects. The material stays non-magnetic. It cleans and maintains easily. Plus, it handles heat and very high or low temperatures without issues. On top of that, 304 stainless steel welds and shapes nicely. So, you can cut, bend, or form it simply for special uses.

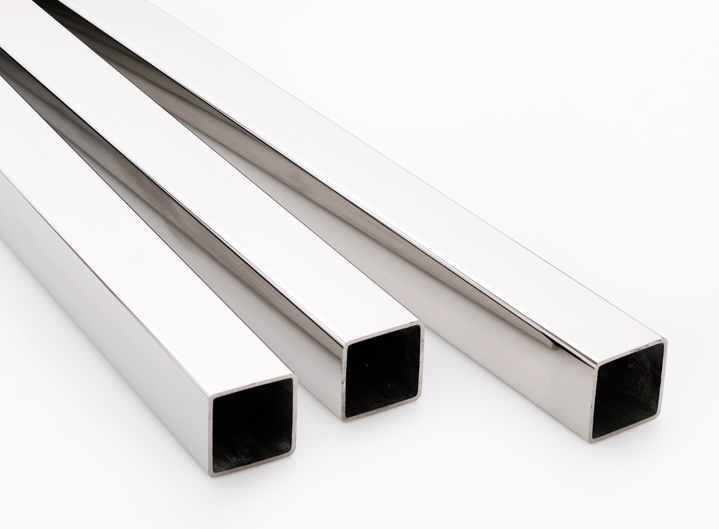

The square shape brings useful and visual benefits compared to round or flat options. Square pipes spread stress evenly over all four edges. As a result, they prove very effective for supporting weight and building frames.

This feature turns it into a great choice for various business, building, and design needs. The even shape also makes making processes easier, like welding, connecting, and lining up. Such tasks prove handy in design setups like railings and barriers. Moreover, square pipes give a neat, fresh style that boosts the look of inside and outside spaces.

Making stainless steel 304 square pipes starts with mixing key raw materials. These mainly include iron, chromium (18–20%), and nickel (8–10.5%). Workers melt these together in an electric arc furnace at very high heat to create liquid steel.

After melting, the steel gets poured into half-finished forms like slabs or billets. Then, these slabs go through hot rolling. This step thins them out and shapes the material into a workable size for pipe making. It also boosts the material’s physical traits by improving the grain setup.

In the following step, the hot-rolled material turns into round tubes. Methods like roll forming or pushing through dies help with this. For welding 304 stainless steel square tubing, options include TIG, MIG, and stick methods. TIG welding stands out as the top pick because of its neat result and exactness.

Once welded, the round tubes move through several shaping rollers. These press them into square forms. The process uses cold working steps. They improve size precision and keep corner curves tight. Cold working makes sure of exact sizes and good surface quality.

After reaching their final shape, square pipes receive surface treatments. These remove dirt and boost rust protection. Pickling clears away buildup and grime from the surface after shaping. Meanwhile, polishing creates a smooth layer that improves both looks and function.

Annealed Surface Finish: The tubes go through an exact annealing step. It boosts rust resistance. It also strengthens the build and gives a even, sleek surface.

To ensure top quality in every group, makers use strict testing approaches. Non-destructive testing (NDT), like eddy current checks, spots inner defects. It does so without harming the pipe’s build. Eddy current tests check weld strength to confirm seams hold up as needed.

Dimensional checks happen with precise tools. They verify the product meets ASTM rules like ASTM A554.

Modern making lines include automatic control setups. They watch important factors like heat, force, lineup, and weld quality right away. These tools cut down on mistakes by people. At the same time, they increase steadiness.

Besides that, quality teams do sample checks on groups. They confirm physical traits like pulling strength, yield strength, stretch rate, and hardness.

In building areas, stainless steel 304 square pipes see heavy use for frames, railings, barriers, covers, and support parts. Their power and rust resistance make them a go-to choice.

These pipes play a key role in work settings too. They help build machine covers, belt systems, gear frames, and support setups. Industrial Applications: Machinery guards; Equipment frames; Conveyor systems

The straight edges and shiny surfaces of stainless steel 304 square pipes fit well for current furniture styles. This includes legs for tables, shelf units, light fittings, and art displays. Furniture Manufacturing: Modern furniture frames; Table and chair legs; Decorative elements

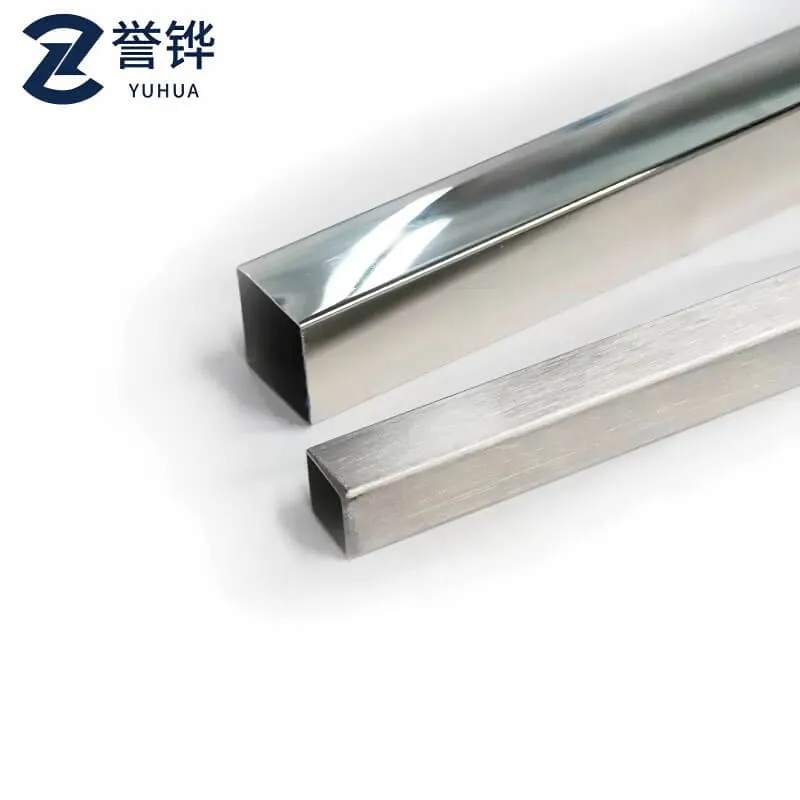

At YUHUA, we take pride in offering high-quality stainless steel products. We started in 2009 in Foshan City. With a complete factory setup and a committed group of engineers, we make a wide variety of stainless steel types. This includes 304 square pipes made with great care.

Our sites hold ISO 9001 approval. We follow global quality rules closely in every production part. We’ve got our own factory line and a skilled team of engineers. This helps us whip up custom products for customers.

We keep steady size accuracy with automatic systems combined with expert work. Our SS 304 square pipes have smooth annealed surfaces. They improve rust resistance for inside and outside uses.

Our 1.5-meter 20x20mm square tubes come from grade 304 stainless steel. They provide strong rust resistance and lasting quality.

We offer tailored size choices too. They fit different project needs, from work frames to fancy building setups.

A: Stainless steel 316 contains molybdenum which enhances corrosion resistance against chlorides. SS 304 is suitable for most general-purpose applications, while SS 316 is preferred in marine or chemical environments.

A: Yes, stainless steel 304 has excellent weldability using common techniques such as TIG or MIG welding. Post-weld cleaning may be required to restore corrosion resistance.

A: Yes, they offer good resistance to weathering, moisture, and many environmental conditions. However, exposure to highly saline or acidic environments may require additional protective measures.