Let me break down what stainless steel seamless pipes are all about. Unlike regular pipes, these don’t have any welded seams — they’re made as one continuous piece. This seamless construction gives them superior strength right from the manufacturing stage.

We typically make these pipes from top-grade stainless steel alloys. The most common ones you’ll see are:

304 grade (the all-rounder)

316L(for extra corrosion resistance)

Occasionally 201 grade (more budget-friendly)

What makes these pipes special? Three key things:

They’re incredibly tough

They resist rust like champions

They hold up beautifully under intense pressure

That’s why they’re the go-to choice for any application where you need both serious strength and perfect structural integrity — think high-pressure systems or critical infrastructure.

You know how we make stainless steel pipes? It all starts with a solid steel cylinder – we call this a “billet.” First, we heat that billet until it’s glowing hot. Then comes the cool part: we drive a mandrel straight through the center, punching out a perfect hollow tube. This initial forming stage sets the foundation for everything that follows. Subsequent stages involve elongating and molding this tube to the specified dimensions through methods such, as extrusion or cold drawing. By sticking to this approach the pipes are guaranteed to be seamless and exhibit mechanical properties when compared to welded pipes.

Let me tell you about these seamless pipes – they’re the real workhorses of industry. What makes them special? No seams means no weak points. None. When things get tough out in the field, these pipes just keep going without missing a beat.

We’re talking about stainless steel here – the good stuff. No seams equals no cracks. No seams equals no rust problems. That’s why they’re the first choice for the toughest jobs out there:

Oil rigs that face brutal ocean conditions

Gas plants handling volatile materials

Chemical factories dealing with corrosive substances

Construction sites where safety is everything

These pipes don’t just survive harsh environments – they thrive in them. When failure could mean disaster, seamless stainless steel is what keeps operations running smoothly.

Seamless steel pipes have a property. Chromium in them reacts with oxygen to form a protective layer that prevents rust and oxidation from forming thus making them resistant to corrosion. Furthermore grades, like 304 and 316L are enhanced with nickel and molybdenum to increase their resistance to pitting and crevice corrosion in settings.

Stainless steel seamless tubes are well known for their qualities as they can withstand pressure and temperature changes without bending because of their exceptional strength.They also last a time and require minimal maintenance, for extended use.

The smooth stainless steel tubes inside reduce resistance for flow and save energy in the process. This enhances the effectiveness of liquid or gas transport systems. Moreover the absence of welded seams also aids in preventing clogs or disruptions, within the tubing ultimately preserving a flow rate.

In sectors such as manufacturing and construction where safety and productivity’re key considerations to think about it’s common to see seamless stainless steel pipes being widely used due to their robustness, in managing high pressures and combatting corrosion while upholding structural stability.

In the oil and gas industry stainless steel pipes play a role in efficiently transporting oil and natural gas under high pressure without any disruptions.They are resistant to corrosion. Can endure tough conditions involving substances such, as hydrogen sulfide or saltwater.It is imperative to utilize these pipes for carrying out drilling activities.

Chemical facilities rely significantly on stainless steel pipes to safely and efficiently handle chemicals under temperatures; steel variants such as 316 L play a vital role in shielding against the effects of acids and chlorides commonly present in chemical environments. A key factor, in maintaining safety standards.

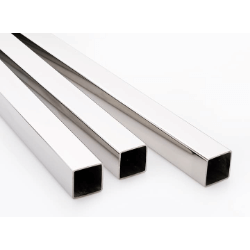

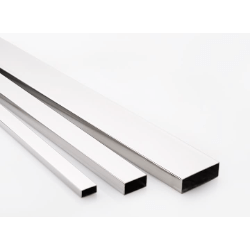

Stainless steel tubes with smooth surfaces are widely used in construction projects. They’re ideal for building frameworks, architectural features, and railings. Why? Because they combine visual appeal with rock-solid durability – exactly what these applications demand.

At YUHUA, we take pride in manufacturing top-grade stainless steel seamless pipes. Every pipe we make is precision-engineered to handle different industrial requirements efficiently. How do we ensure quality? By strictly following recognized standards like ASTM A554 and AISI specifications. This guarantees reliable performance in all sorts of applications.

Want to see our full product lineup? Just head over to YUHUA’s product center.

At YUHUA, we’re all about making top-quality stainless steel seamless pipes. These aren’t just good pipes – they meet the toughest quality standards you’ll find anywhere.

We don’t cut corners on materials. That’s why we work with premium grades like 304 and 316L stainless steel. What does this mean for you? Pipes that:

Last forever

Can take a beating

Won’t rust

Every material we choose gets picked for a reason. We test and retest to make sure our pipes perform exactly how you need them to – no matter where you’re using them.

Now, about our 304 grade tubes – these bad boys have made a name for themselves. They’re corrosion-resistant champs that meet all the big standards (ASTM, AISI, EN). That’s why everyone from construction crews to food factories trusts them day in and day out.

Similarly our 316L steel circular pipes offer protection against chlorides and acids making them an excellent option, for demanding environments commonly seen in chemical industries.

At YUHUA we understand the demands of every project and work diligently to fulfill them with precision and dedication. We offer a variety of customization options for our stainless steel pipes with notches to cater to needs. Our products are available in sizes, shapes (including square and rectangular) and finishes (like polished or brushed) allowing us to cater to various purposes such, as architectural projects, industrial equipment components and decorative enhancements.

Our oval shaped stainless steel closet rod is 3 inches long. Can be customized to meet the storage needs of homes and businesses alike.

At YUHUA we emphasize the importance of maintaining high quality standards at every stage of production to ensure quality control measures are in place throughout the entire process.We apply techniques, like TIG welding and eddy current testing during our manufacturing procedures to ensure the robustness and longevity of our welded connections.Additionally we perform pressure tests to validate the endurance of our pipes when subjected to pressure scenarios.

At YUHUA, we stand behind every pipe we make. Here’s how we prove it:

Full material traceability documents. Official mill test certificates with every order. This paper trail guarantees our stainless steel pipes always meet top quality standards.

Transparency isn’t just a buzzword for us – it’s how we earn your trust. Why? Because your satisfaction comes first. Always. No exceptions. Our secret weapon? A team that actually listens. We don’t just take orders – we dig deep to understand exactly what you need. Then we deliver solutions that surprise even the toughest critics.

A: Seamless stainless steel pipes outperform welded ones due to their lack of weld joints or seams that can create vulnerabilities under pressure or stress situations.Their consistent structure offers improved characteristics like increased tensile strength and superior resistance to corrosion.

A: Yes, YUHUA’s seamless stainless steel pipes are more than capable of withstanding conditions, such as those found in marine environments or chemical plants thanks to their outstanding resistance to pitting and crevice corrosion – they really excel in tough situations like these.

A: YUHUA ensures the durability of its products by utilizing top notch materials such as 304 and 316 L grades along with testing procedures, throughout the manufacturing process guaranteeing that our seamless stainless steel pipes offer extended durability with minimal upkeep needs