Stainless steel 304 welded pipes are legit all-stars, popping up everywhere for their versatility and toughness. They’re a big deal in tons of industries thanks to their killer mix of strength and chemical makeup. These pipes shine in places needing serious resistance to rust and corrosion, like super harsh environments. Think food and beverage plants, chemical factories, construction setups, plumbing systems, and even hospitals.

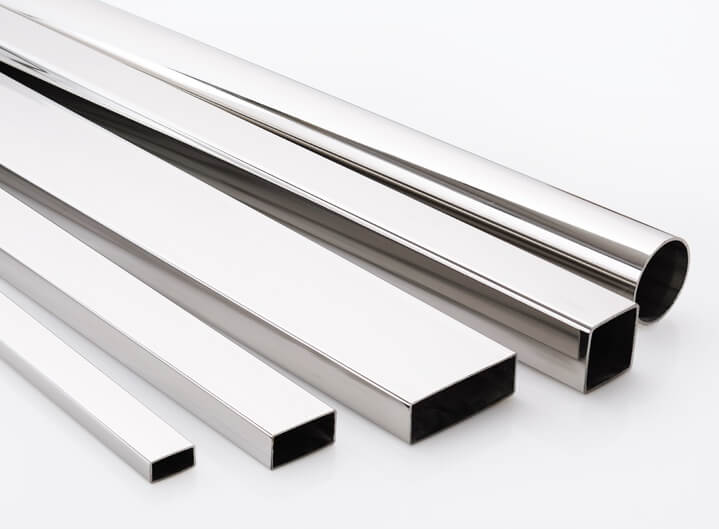

Plus, stainless steel 304 welded pipes are some of the most popular stainless steel gear out there, known for shrugging off rust, being crazy strong, and working for all sorts of jobs. They’re not just for industrial stuff—think handrails, car trims, or fancy building designs.

The hype around stainless steel 304 welded pipes comes from their next-level material traits. These pipes get their strength, bendy vibes, rust-proofing, and long-lasting power from a perfect mix of elements. They’ve got about 18% chromium and 8% nickel, which make them laugh off rust and oxidation.

On the mechanical side, they’re rocking a yield strength of around 205 MPa and hardness stats like Brinell 201 and Rockwell B92. Stainless steel 304 pipes are clutch for high-pressure systems because they’ve got mad tensile strength, great stretch, and solid hardness.

These perks make stainless steel a champ for handling wild temperature swings or chemical exposure.

Seamless pipes are the go-to for super high-pressure jobs because they’re one solid piece, but welded pipes bring their own game. Welded pipes are easier on the wallet since they waste less raw material in production.

Plus, welding tech’s gotten so good that welds are crazy strong now. Welded pipes can be made in longer lengths with even wall thickness. That makes them perfect for structural gigs where pressure’s not insane but consistent sizing is key.

One of the best things about stainless steel 304 welded pipes is how easy they are to weld. Easy to Weld and Fabricate: Ideal for custom designs and modifications. Whether you’re using TIG or MIG welding, the austenitic structure lets you fuse it smooth without cracking or losing rust resistance—especially with the right filler materials.

The low-carbon version (304L) makes it even better by cutting down on carbide buildup during welding.

Welding does create heat-affected zones (HAZ) that can tweak the metal’s structure near the weld. But with slick modern tricks like automated TIG welding and post-weld heat treatments when needed, those effects are no big deal.

ASTM A554 stainless steel welded tubes are precision-engineered tubular products designed for architectural, decorative, and structural applications. Quality checks like eddy current testing make sure the weld holds up even under stress.

We at YUHUA have been killing it in stainless steel since we started in 2009 in Foshan City’s Nanhai District. As one of China’s top dogs in stainless steel solutions—including grades like 200 series through 400 series—we bring over a decade of know-how backed by ISO 9001 certification.

Our integrated factory line and pro engineering crew let us drop custom products that hit global standards across industries.

Our stainless steel 304 welded pipes are next-level with their slick finish, spot-on sizing, top-tier rust resistance, and easy fabrication. We use cutting-edge TIG welding tech and hardcore quality checks like hydrostatic pressure testing and full material tracking.

Whether you need round tubes for factory machines or square pipes for fancy building designs, we deliver consistent quality at a price that doesn’t break the bank. Our innovation’s snagged us over ten patents and props as a national high-tech enterprise.

It can take the heat, the low to high pressure, and the moisture- or low to high chemical-exposure you can throw at it. This makes it a beast in boilers, steam lines, chemical reactors, or exhaust systems where staying stable under heat is a must.

Plus, High Strength: Suitable for high-pressure and high-temperature applications. ensures it stays reliable even when things get rough.

Excellent resistance to rust, oxidation and most chemicals. This makes our pipes perfect for marine setups or chemical plants where saltwater or acids would chew up other materials fast.

Even outdoors or underground with crazy moisture changes, our SS 304 welded pipes keep their strength over time.

From a planet-friendly angle, their recyclable material supports sustainable living. Their long lifespan and recyclability cut down waste compared to stuff like PVC or galvanized iron.

Plus, the stainless steel surface is smooth and cleanand easy to clean and maintain.—saving water during regular upkeep.

They start by melting raw materials into billets, then rolling ‘em hot or cold into pipe or tube shapes. For welded ones, a flat strip (coil) gets shaped and then welded lengthwise with TIG or laser methods, depending on the job.

This setup gives us wiggle room to make custom lengths with precise wall thickness while keeping everything uniform across batches.

At YUHUA, we follow ASTM A554 standards to the letter for all our SS 304 welded pipes. Our hardcore testing includes:

Eddy current testing

Hydrostatic pressure tests

Dimensional inspections

Mill test certificates

These steps make sure we’re not just checking boxes but delivering pipes that crush it worldwide.

Q: What’s the difference between stainless steel 304 welded pipe and seamless pipe?

A: Seamless pipes are made without welds, so they handle higher pressure; but welded pipes are cheaper and work great for structural or less intense systems where cost matters more than pressure.

Q: Is stainless steel 304 good for drinking water systems?

A: Hell yeah. It’s suitable for the processing, storage and transportation of food, including potable water due to its non-toxic nature and resistance against microbial growth inside pipelines.

Q: How long do stainless steel 304 welded pipes last?

A: With proper setup, Stainless steel has good corrosion and wear resistance and long service life. making SS 304 welded pipes a durable choice that can last decades even under challenging conditions.