Both stainless steel pipes and tubes come from alike materials. Yet their uses and sizing rules vary quite a bit. A stainless steel pipe mainly handles moving liquids, gases and solids. So its size relies on the inside diameter (ID). This way, it helps figure out flow speed and pressure capacity.

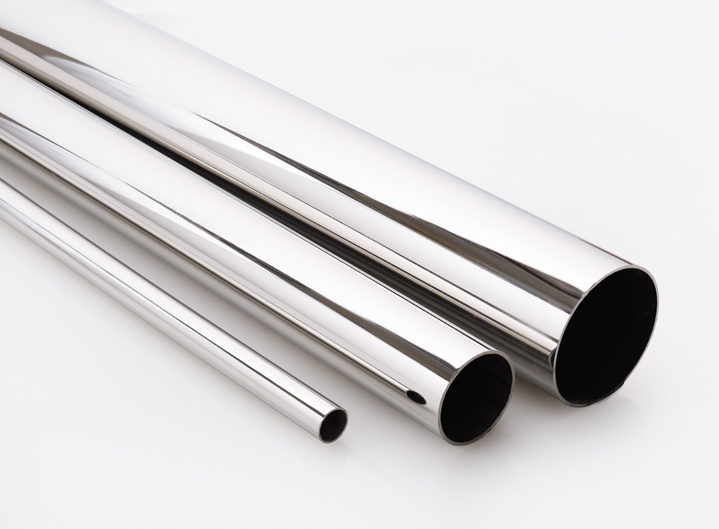

By comparison, a stainless steel tube often fits structural, mechanical, or decorative roles. People size tubes by the outside diameter (OD). They also demand closer size limits. What’s more, pipes stay mostly round. Tubes, however, can take square, rectangular, or round shapes.

The gaps between pipes and tubes touch all parts of planning and use. Pipes get built to move fluids under pressure. Thus, their making follows firm pressure levels and approval rules. Pipes tend to have thicker, tougher walls than tubes. This fits them well for strong-pressure setups.

Tubes need close size rules to fit right in building setups. They usually feature slimmer walls and bendier links. So they work great for weight-holding frames. Or for places where style counts, like railings or medical gear.

Picking the grade really shapes how stainless steel pipes and tubes work. Common types cover 304 and 316. 304 Stainless Steel Pipes count as one of the most common stainless steel items. They offer great rust protection, solid power and wide range. Meanwhile, 316L Stainless Steel Round Pipes make a prime pick for fields needing top rust guard, lasting build and work in rough spots.

These material gaps also shift price and handling ease. Take the low carbon in 316L. It boosts joining skill. This helps a lot in drug or sea uses.

The surface treatment can strongly shape both practical side and looks. Tubes face a careful heating step. It lifts rust guard, boosts build strength and gives an even, sleek face. This suits them for seen building parts or clean spaces.

Coarser treatments might do for buried pipes. There, looks and clean needs don’t top the list. Heated or shiny surfaces also change how easy cleaning and care get.

Stainless steel pipes get built to handle tough high-pressure fluid flow. Stainless steel pipes serve to carry gases and liquids. So grasping their load limit matters. They follow strict rules like ASTM A312 or ASME B36.10M. This keeps things safe under stress.

Tubes’ better size match makes them a better choice where exact fit counts. Tubes stand out with exact sizes and tight limits on outside diameter and wall depth. For that reason, they go into scaffold setups, furniture bases, car parts and surgery tools.

Pipes can get made by seamless pushing or joining ways. Seamless pipes handle pressure well. Joined pipes, like our 304 stainless steel picks, often get heating steps. These raise power and rust guard.

Tubes commonly face cold pulling steps. These sharpen size match and surface state. The tubes face a careful heating step. It raises rust guard and build strength. So they hit high marks for build strength and joining skill.

Pipes prove key in many work areas:

Oil & Gas: Used in pipelines, refineries, offshore rigs.

Chemical Processing: For transporting corrosive fluids.

Water Treatment Plants: High-pressure water delivery systems often rely on durable stainless steel piping solutions.

Tubes enter uses that need solid support or nice style:

Construction: Handrails and balustrades.

Automotive: Roll cages, exhaust systems.

Medical: Surgical instruments and hospital equipment frames.

We at YUHUA have stuck to stainless steel pipe making since 2009. Our spot is in Foshan City. We focus on top-grade stainless steel goods in types like 201, 304, 304L, 316L, 410 and 430. Our modern factory setup and skilled engineers let us give standard and custom fixes. These meet world work needs.

Our stainless steel pipes closely follow world rules like ASTM and DIN. Take our 1.5-meter 20x20mm square tubes. They come from grade 304 stainless steel. These give strong rust guard and lasting power. Each good faces tough checks like eddy current looks. We back them with factory test papers.

We aid fields like food handling, building, oil & gas, water treatment, automotive and sea work. Our products are ideal for both indoor and outdoor applications due to their superior corrosion resistance.

We offer tailored dimensions, surface finishes (annealed or polished), packaging options and even grade selection to match your exact project requirements.

A: Stainless steel pipe is typically measured by its internal diameter (ID) because it’s designed to carry fluids or gases where flow rate matters most; tubes are measured by outer diameter (OD) as they are often used structurally where external dimensions affect fitment.

A: While it’s technically possible in low-pressure systems, tubes may not meet pressure ratings required for industrial fluid transport; pipes are engineered specifically for such use cases with appropriate wall thicknesses and certifications.

A: Consider the application’s purpose (fluid transport vs structural use), required strength or pressure rating, dimensional tolerances needed, corrosion resistance requirements based on environment and relevant industry standards or codes of compliance.