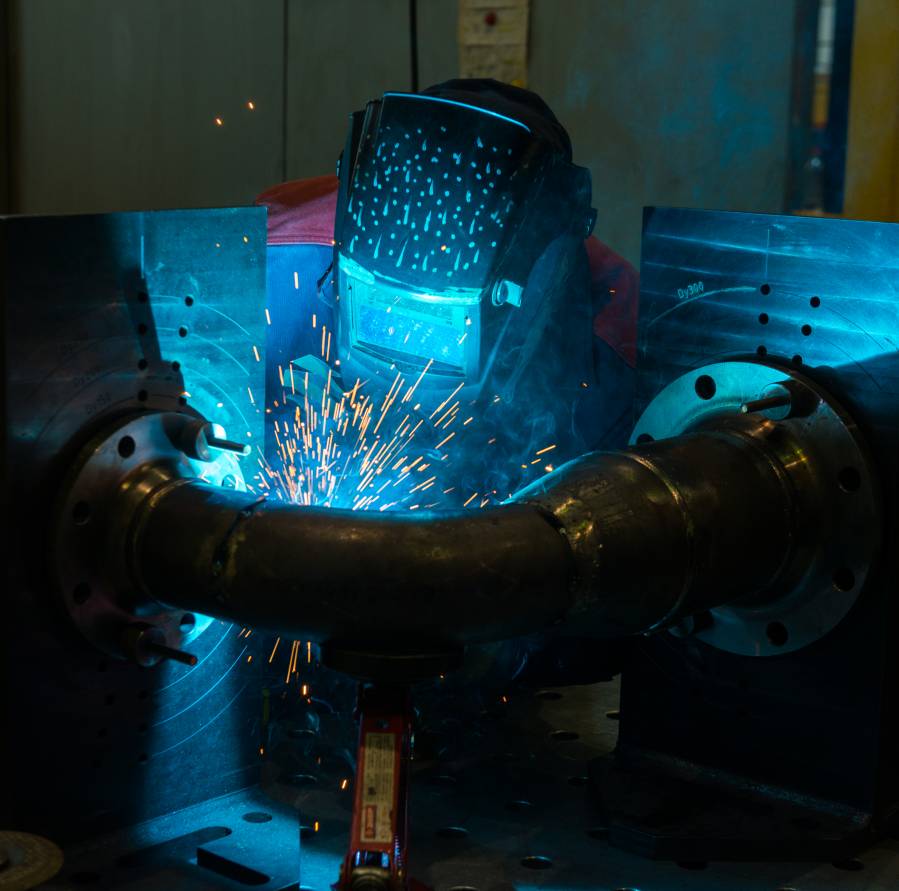

Laser welding has grown more popular for joining stainless steel pipes because of its excellent accuracy and speed. A key factor is that it provides sharp precision and neat welds with little warping. This matters a lot when handling thin-walled or narrow pipes. Stainless steel stands out for its strong build and rust resistance. Thus, it needs a joining method that keeps its strength and surface intact.

Laser welding also creates sturdy, even connections with low heat use. This careful heat control cuts down the chance of material bending or burning through. As a result, it works well for sensitive or exact tasks. For example, it suits medical or food-safe pipe systems.

When compared to common techniques like TIG or MIG welding, laser welding excels with purer outcomes and quicker rates. Laser welding skips filler materials. So, it becomes a tidier and more effective process. This leads to less cleanup after welding. There’s reduced spatter and rusting too.

Moreover, laser welding forms a slim heat-affected zone (HAZ). This helps keep the metal qualities of stainless steel. It’s vital for holding onto rust resistance and physical power.

The main idea of laser welding uses a sharp laser ray to soften and blend metal parts. The method is famous for its accuracy and quickness. It allows very fine, top-notch welds. The process can run in steady or burst modes, based on the job and pipe size. Steady mode fits longer edges. Burst mode suits slimmer parts where heat control is key.

Fiber lasers lead as the best pick for automatic pipe welding setups. This tech gives top beam clarity and power savings. It fits stainless steel jobs very well. It’s great at deep reach with small twisting.

CO₂ lasers get used too. But they suit bulkier stuff more. They provide solid power. Yet, they run less smoothly than fiber lasers. Their light path setup can be trickier too.

Laser welding does great in fields where exactness can’t be skipped. Think food handling, drug making, and plane building. It lets you make close-fit links and nice-looking seams without added material. In areas where looks count as much as work—like health or food—laser welding gives a sleek, eye-pleasing end.

The starting cost might be steeper. But laser welding brings big savings in the long run. It cuts the need for after-join finishing. Lower heat means fewer flaws and less waste. Plus, it uses less power than old ways. That’s due to its smart energy flow and faster times.

Laser welding fits perfectly here. It makes clean, gap-free joins that are simple to wash and hard against dirt. It’s good for handling, storing, and moving food.

Drug making needs clean spaces with even pipe insides. The sharp work and purity of laser joins make them just right for this area.

These fields need rust-proof links that handle high force and heat. 316L Stainless Steel Round Pipes resist pitting, gap rust, and chemical harm well. So, they work great in sea, chemical, and drug fields.

Laser welding tools fit best in big-run shops where machines can run full tilt. If you do large lots or steady lines, the payoff comes faster. That’s from less worker time and shorter stops.

Laser welding demands exact joint setup. Gaps or off-angles can cause poor melting or weak spots. So, top prep is a must.

The first buy-in for laser gear is pricier than old setups. But gains in power, work, and stuff often make it worth it. Still, steady upkeep and worker training are needed for best results.

At YUHUA, we focus on making fine stainless steel pipes that match laser welding needs. We started in 2009 in Foshan City. Now, we’re a top maker in China with ISO 9001 approval and over 10 owned techs.

We’ve earned trust for steady quality and help in world markets. No matter if you’re in drugs, food work, or chemical making, our pipes hit tough field rules.

Our stainless steel pipes have even wall sizes and sleek outsides. This ensures solid weld work batch after batch. The stainless steel outside is even and pure. It doesn’t grab dust or grime easily. And it’s simple to wash and keep up.

We supply a broad choice of types—like 201, 304, 304L, 316L, 410, and 430—and forms such as round, square, rectangular, and oval pipes.

A: Yes, mainly when sharpness, quickness, and small warping matter most. Laser welding runs smoother in big-run or machine setups.

A: Laser welding suits slimmer stuff best. But it can manage thicker pipes with extra runs or mixed ways.

A: Not much. With right settings, it keeps the rust-proof traits of stainless steel. That’s because of small heat use.